OFFER

Thermographic

analysis

OFFER

To professional equipment, for the needs of our customers, ROSINSKI PACKAGING examines the flow of the medium in cooling systems by the thermographic analysis. This kind of analysis allows us to check if the cooling systems is properly done and the injection process is optimised.

Analytical process

Process technological parameters

Infrared monitoring

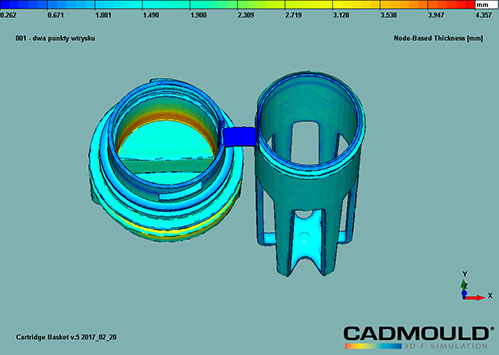

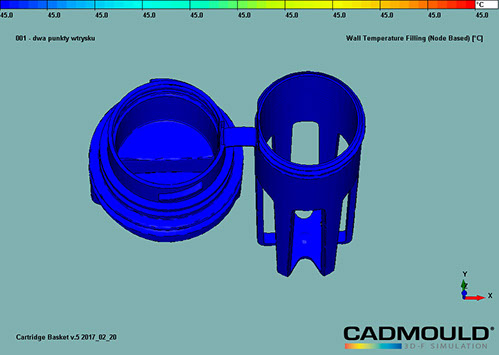

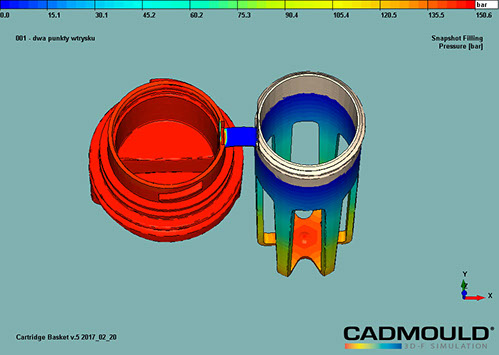

In processes of polymeric material injection manufacturing the factors, such as: material and tool temperature and material injection pressure are very important. These factors determine the characteristics and the structure of final products. The constant process of exchanging the heat between the molder and the mould is launched by putting the formed polymer to the mould. This process lasts until the molder is removed. This is why thermal processes determine how the material will be shaped in the mould and what the characteristics of the injected mould will be.

The analysis using a thermographic technique is a way of monitoring how the manufacturing process runs. A thermographic image is a source of information about the process progress and changes that occur during its duration. Using the infrared technology enables to stabilise the range of the process temperature. In ROSISNKI PACKAGING we measure the mould surface temperature so that we could optimise the injection process. We detect thermal nodes in the insert areas thanks to a tool thermal analysis which lets to do some changes in the cooling system. It results in shortening the manufacturing cycle and improving the quality of produced parts or products.

See also

3D metal print DMLS / SLM

Designing and optimisation

Conformal cooling

The company is located in the south of Poland in Bielsko-Biała, in the center of eastern-central Europe, where the distance from Bielsko-Biała to Warsaw, Prague, Budapest, Vienna or Dresden is comparable.

2017 Rosinski Packaging. All Rights Reserved. Developer: BardziejKreatywni.pl